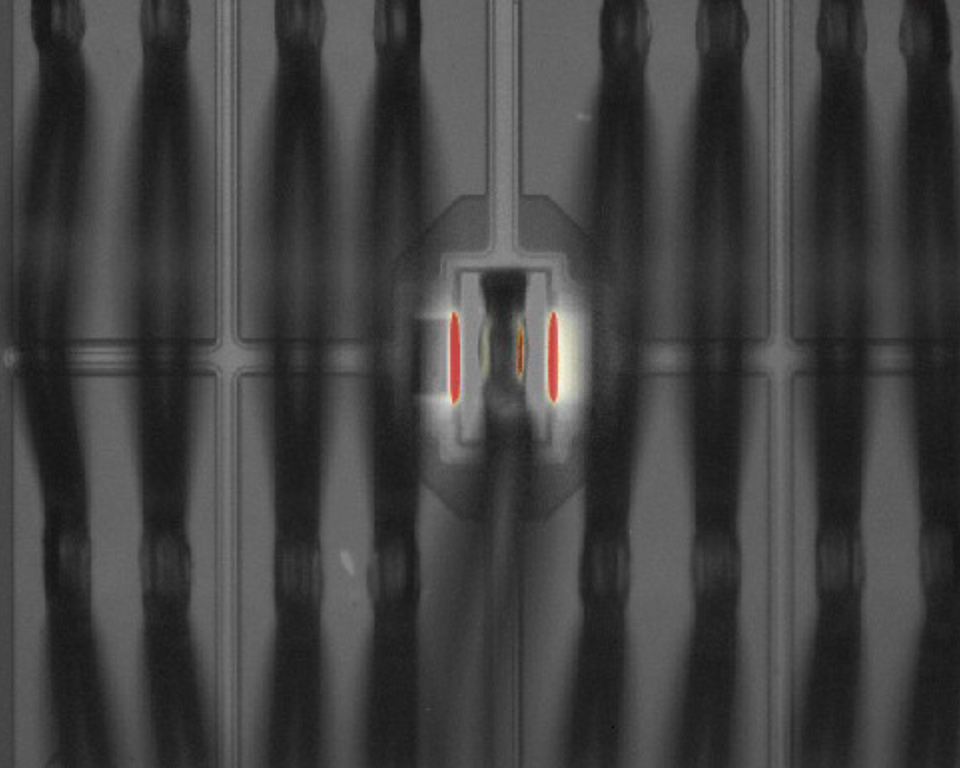

Description of lock-in thermography analysis

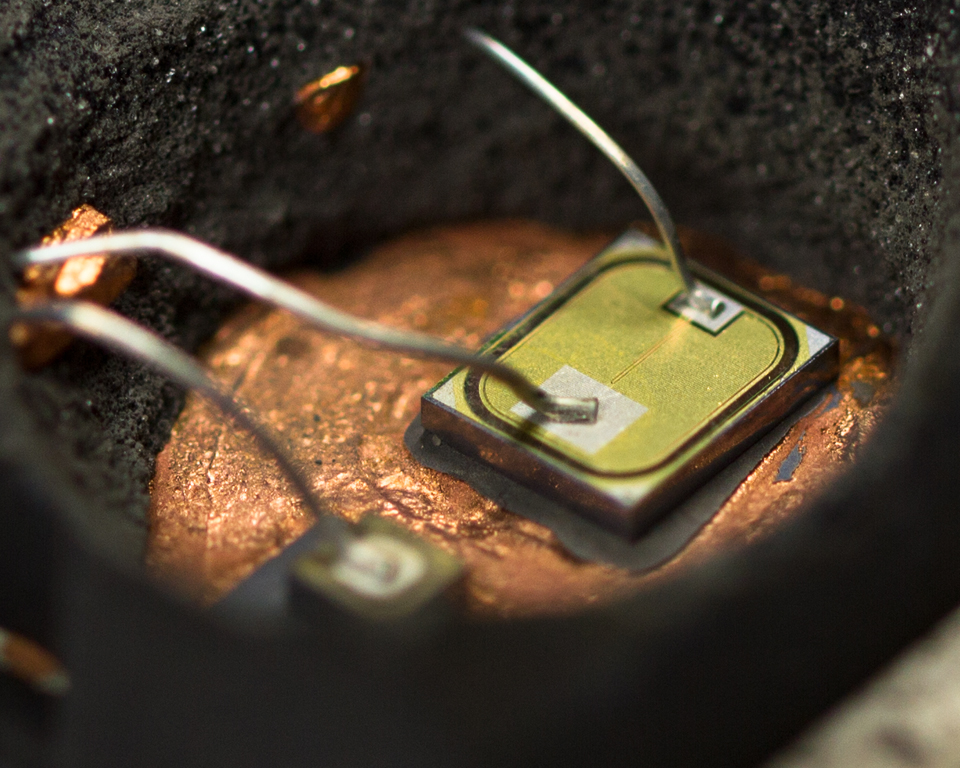

- Detecting of failed power electronic devices such as IGBT, MosFETs, diodes, and resistors

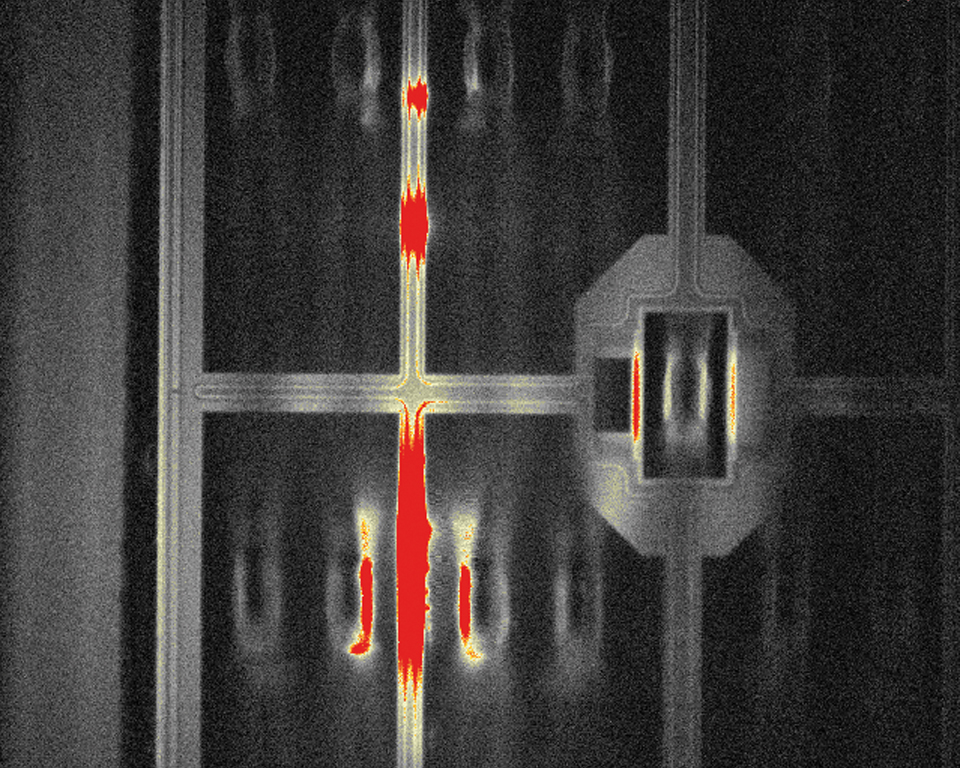

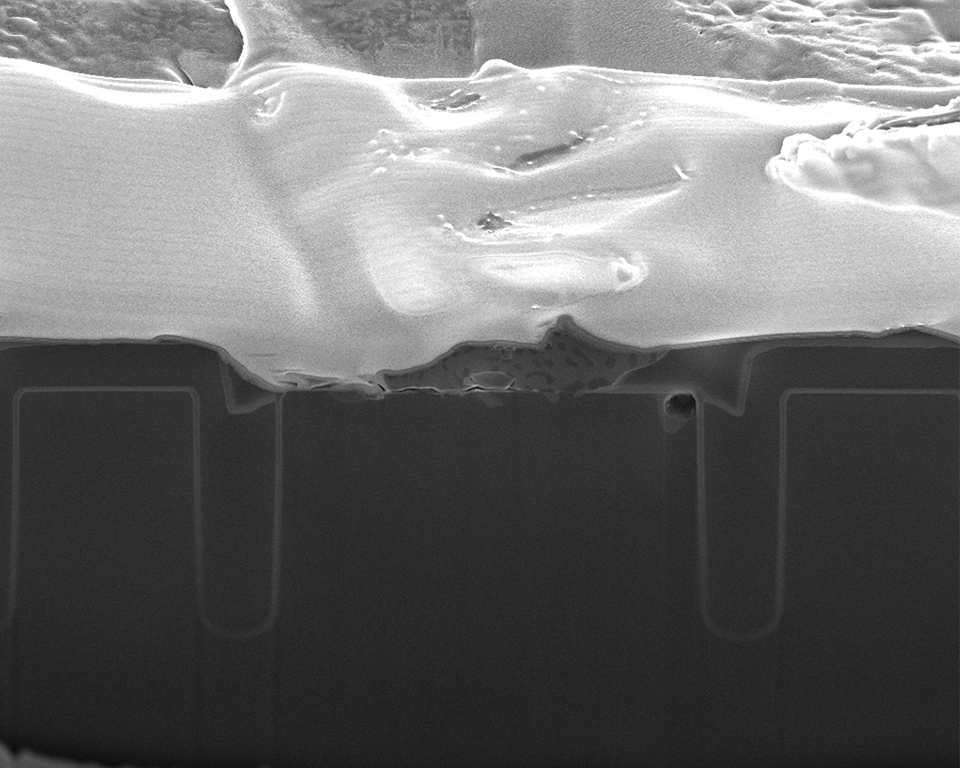

- Analysis of short circuits, ESD defects, oxide damages, edge termination defects, avalanche brake down, whiskers, and electrical conductive contamination

- High sensitivity for hot spot detection with a heat dissipation in the μW range

- 2D / 3D defect localization for further destructive analysis to identify the failure mechanism

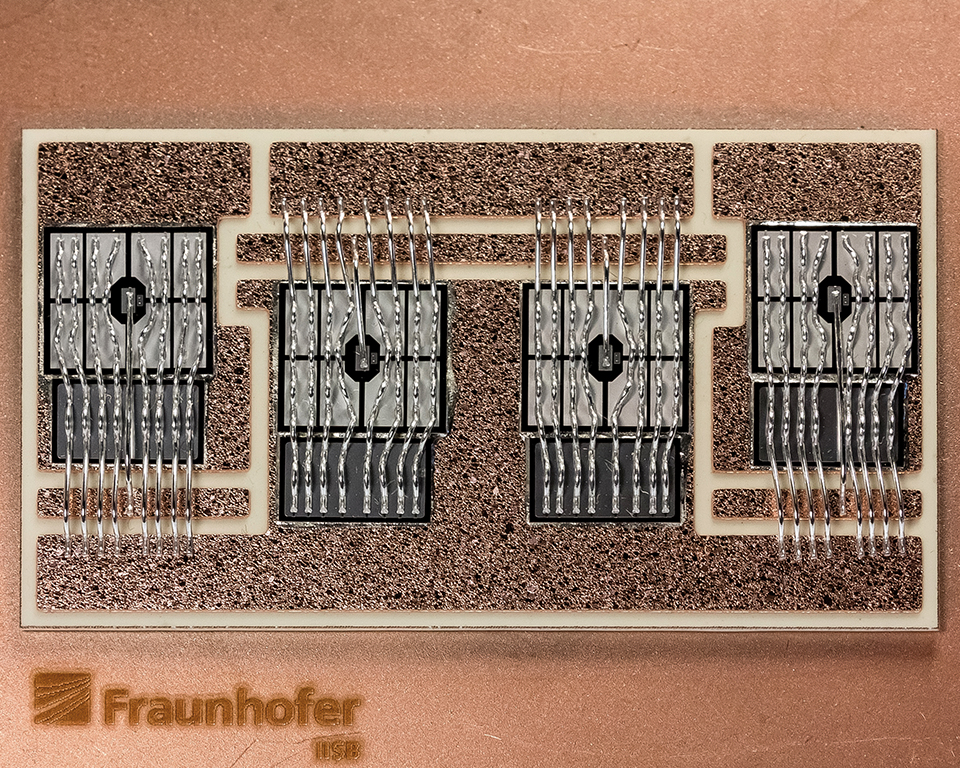

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB