Custom-tailored SiC Services with One-stop Solutions from Material to System

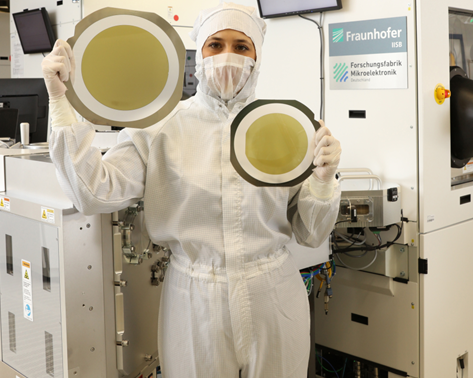

Drawing on 20 years of cooperation with partners from SiC industry and research, Fraunhofer IISB has been established as Germany‘s hotspot for silicon carbide power device manufacturing on a 150 mm SiC line. Our mission is to share our many years of experience with the customers and to provide them with distinct SiC power device prototypes for newly arising markets. We are currently ramping up our 200 mm SiC line - many tools and processes are ready and technological gaps will be closed soon.

4H-SiC is the ideal semiconductor for the realization of high-voltage and high-power electronic devices due to its outstanding material properties. With SiC services as a crosscut topic of the departments of Fraunhofer IISB and in close collaboration with the in-house brand π-Fab, we offer R&D services ranging from material development and prototype devices to module assembly and mechatronic systems.

Core competences

- Simulation and modeling

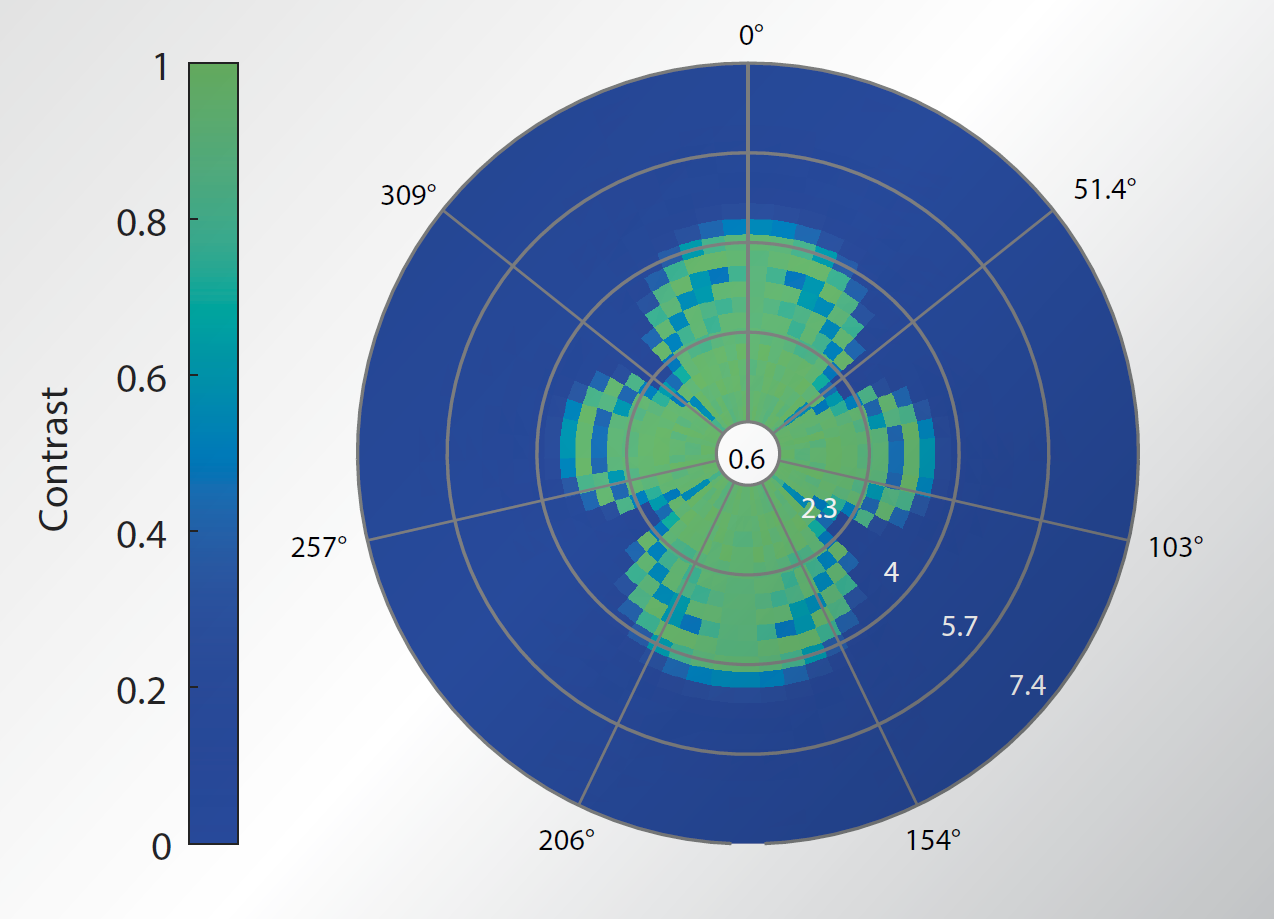

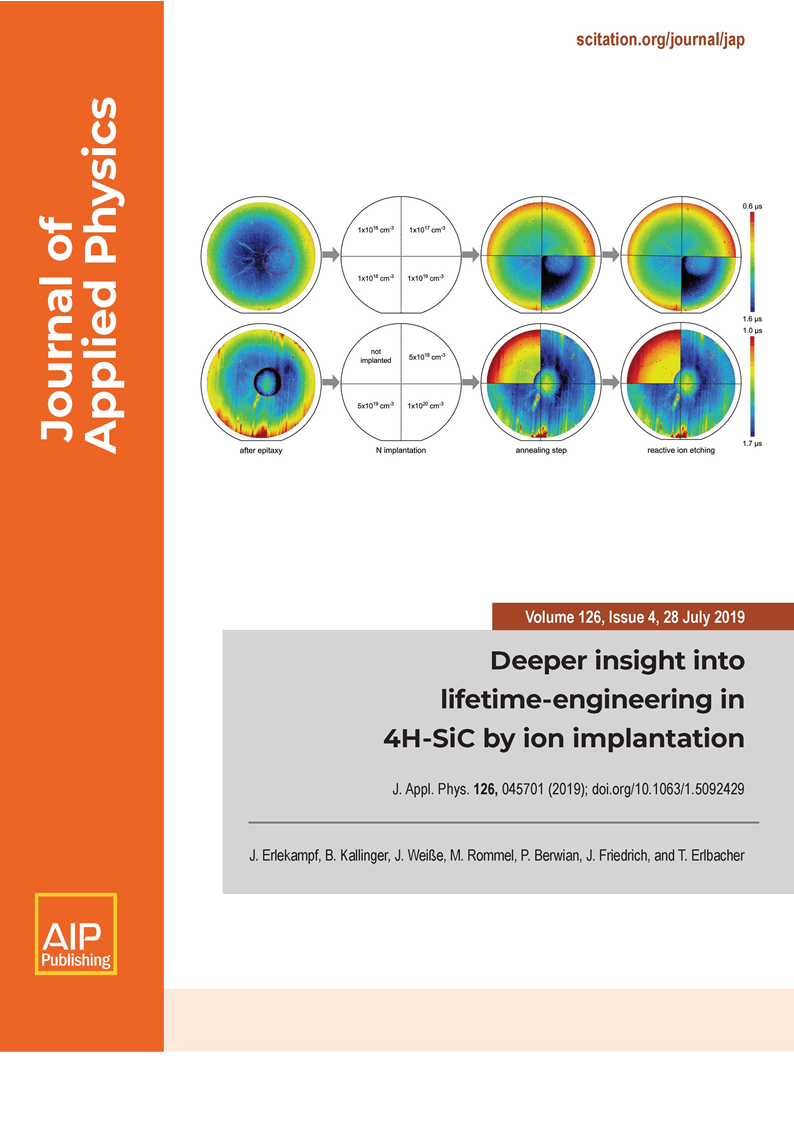

- Homoepitaxy and defect engineering

- Device and circuit design

- Full power device manufacturing

- Wafer thinning and packaging

- Device characterization

SiC power device prototypes

- Diodes (SBD, PIN, MPS)

- MOSFETs (planar, trench)

- Specific devices (bipolar, CMOS, sensor)

- Industry collaboration towards qualified high-volume foundries

Markets

- Hybrid electric vehicles and electric vehicles

- Renewable energies (wind, solar)

- Power grid

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB