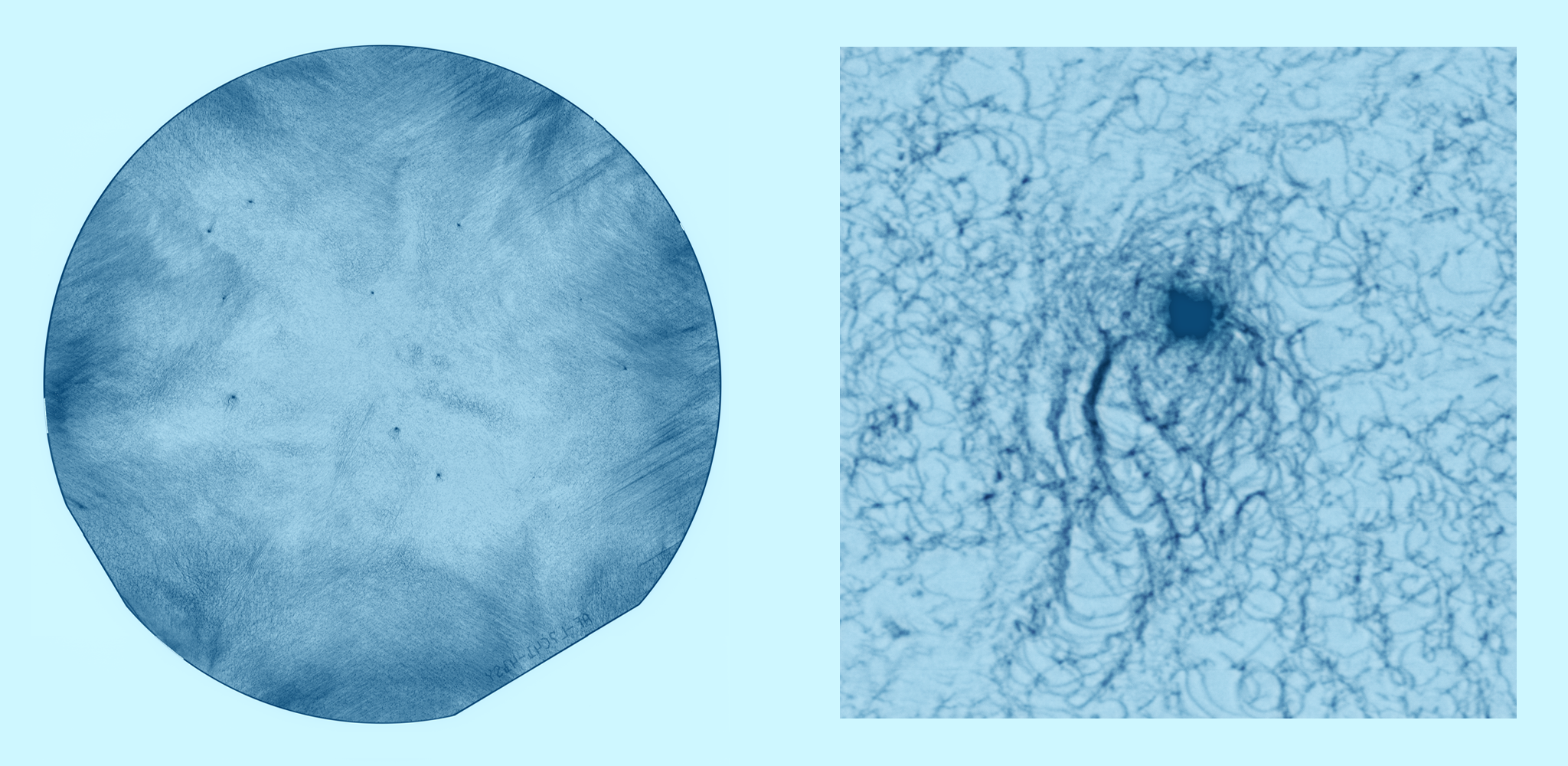

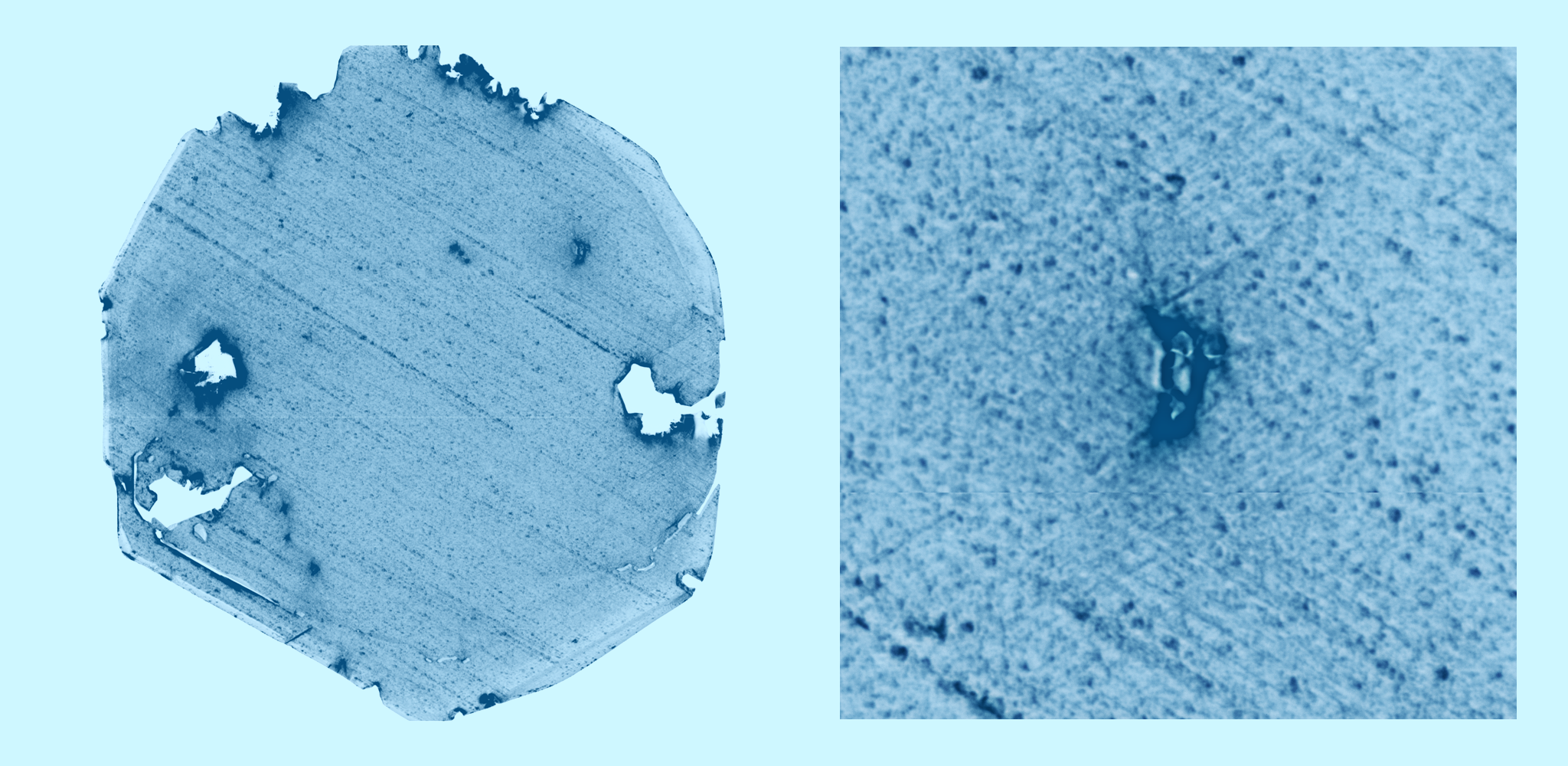

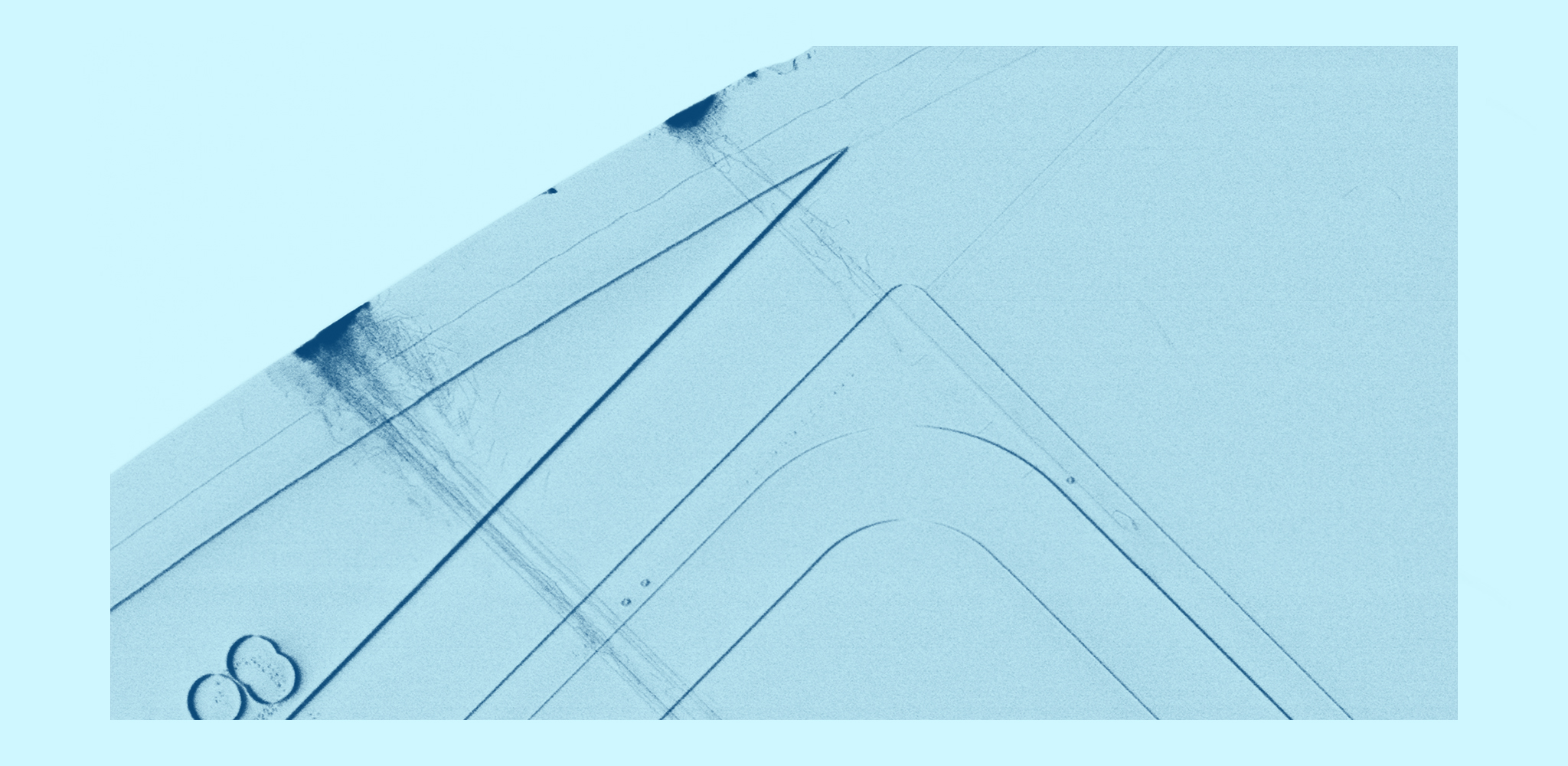

You benefit from our full-surface and non-destructive method as well as feedback loops within a few days. Our experts analyze your samples to support you in quality assurance during your production process or in R&D tasks. This may involve very local defect analysis, for example. We also provide the generation of statistical measurement data based on a large number of wafers to control your material quality on the entire wafer area during ongoing production. The amount and different types of dislocations, slip lines, dislocation networks, (small-angle) grain boundaries, inclusions, precipitates, scratches, bends, etc. are mapped and quantified on the samples.

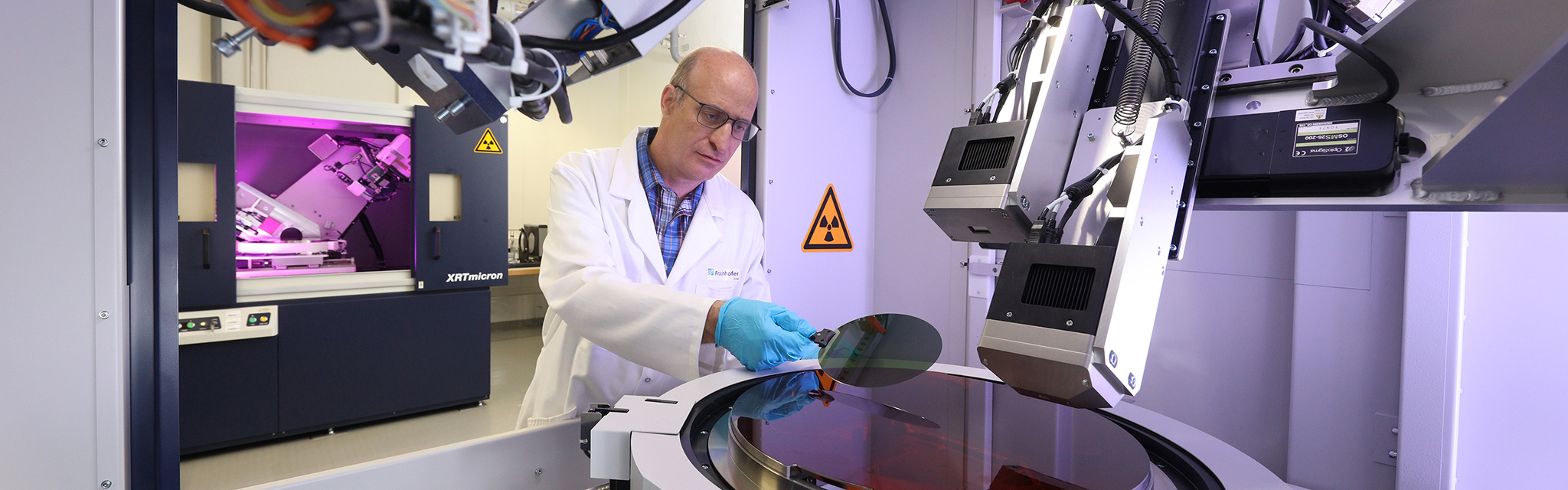

We use fast, high-resolution XRTmicron X-ray topography systems from our strategic partner Rigaku. These systems are characterized in particular by the different X-ray sources copper, molybdenum, silver and chromium. In combination with the application of large-angle goniometers, a wide range of diffraction conditions is possible. Therefore, the X-ray topography method is suitable for different types of single crystalline materials:

- Semiconductors: Si, Ge, diamond, SiC, GaN, AlN, GaAs, InP, CdTe, CdZnTe

- Oxides: sapphire, ruby, garnets, vanadates, niobates, quartz

- Halogenides: fluorides, bromides

The XRTmicron systems used can be operated in both transmission and reflection modes This allows defects in the volume of the sample to be detected or near-surface defects to be quantified. Furthermore, the X-ray systems are equipped with a standard and high-resolution XTOP CCD camera. This results in a spatial resolution of 5.4 µm and 2.4 µm per pixel, with a single image size of 18 mm x 13.5 mm. Full wafer mappings and detailed defect imaging of regions of interest are possible under various diffraction conditions for sample sizes up to 300 mm in diameter. The systems are equipped with a special slit arrangement to perform high-resolution cross-sectional topography measurements with 3D defect reconstruction. Through this process we provide detailed depth information over the entire thickness of your sample.

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB