Fields of research and service

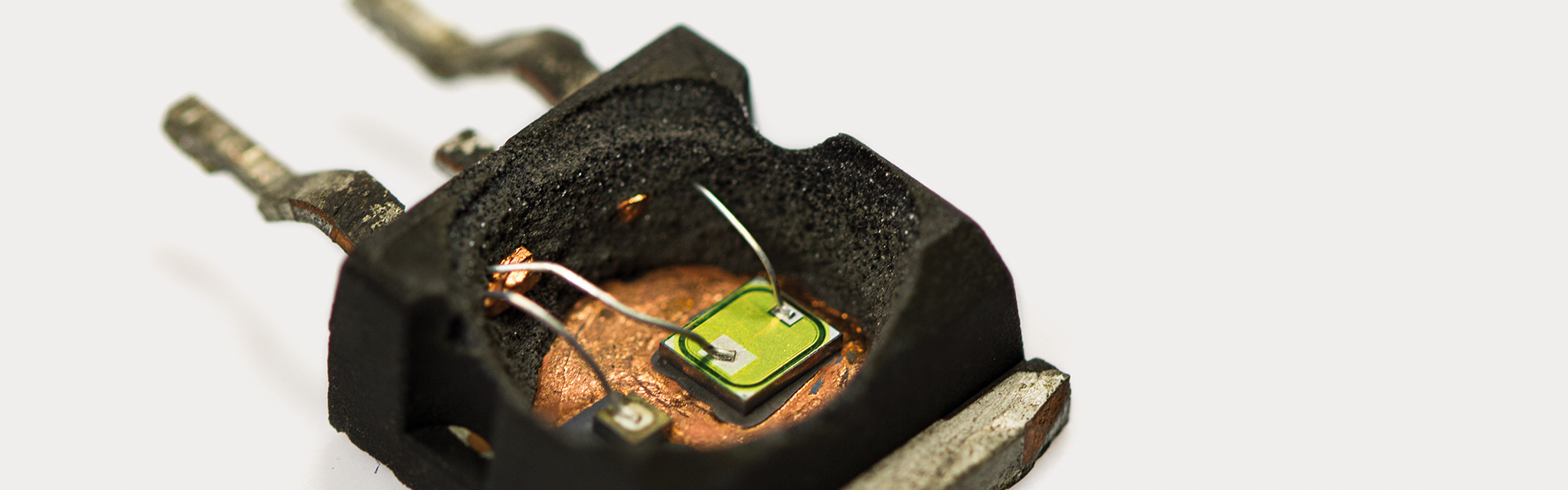

- Investigation of field returns

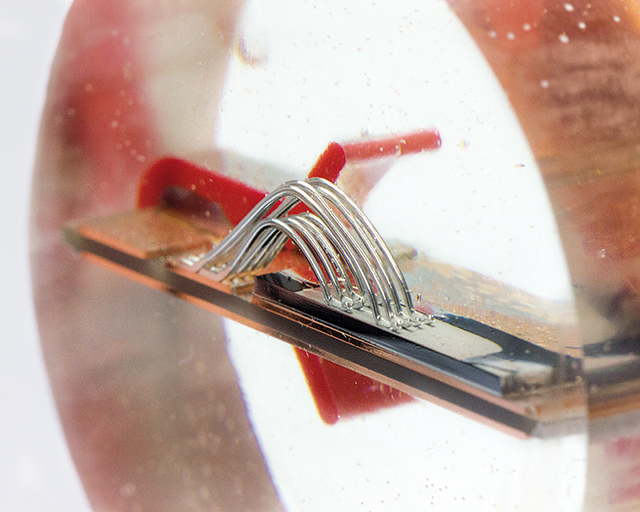

- Characterization of samples accompanying in-house and external life time tests such as active power cycling

- Analysis of new packaging concepts and joining technologies, for instance sinter technology versus soldering

- Competitive analysis of power electronic systems, modules and devices like power electronics of hybrid vehicles

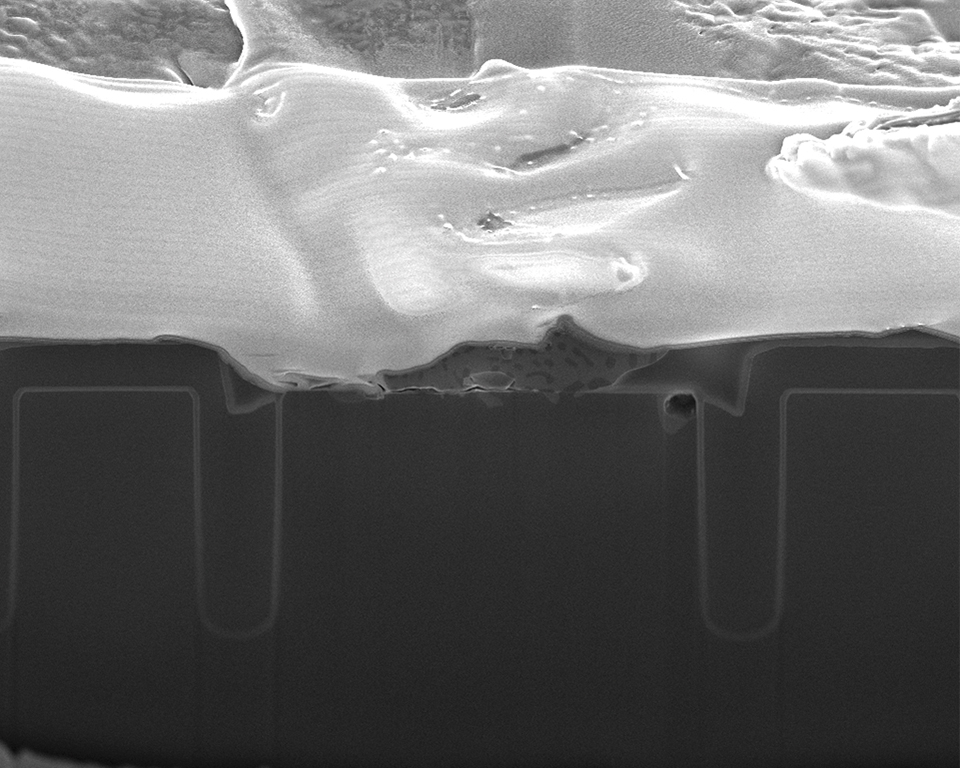

- Physics of failure analysis, material characterization for parameterization of existing life time models or enhanced ones

- Interpretation of test results and failure mechanisms such as edge termination break down of semiconductor devices

- Consultancy on the different investigated failure modes, for instance chip damage due to improper bond wire process parameters

- Partial discharge measurement

- Optical microscopy for searching for dendrites

- Laser interferometry (for analysis of coating quality and coating thickness)

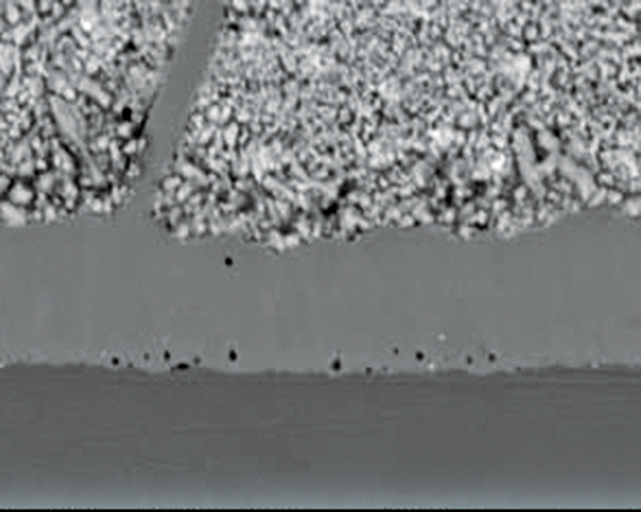

- Cross-sectioning by sawing, grinding, polishing

- Cross-sectioning by femto-laser curing

- Comparative tracking index

- Scratch test

- Decapsulation of mold compounds as well as silicone gels

- Scanning electron microscopy (SEM) and elemental analysis with energy dispersive X-ray spectroscopy (EDX), distribution and quantity

- Focused ion beam (FIB), high speed cutting by plasma

- Thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC)

- Fourier-transform infrared spectroscopy (FTIR)

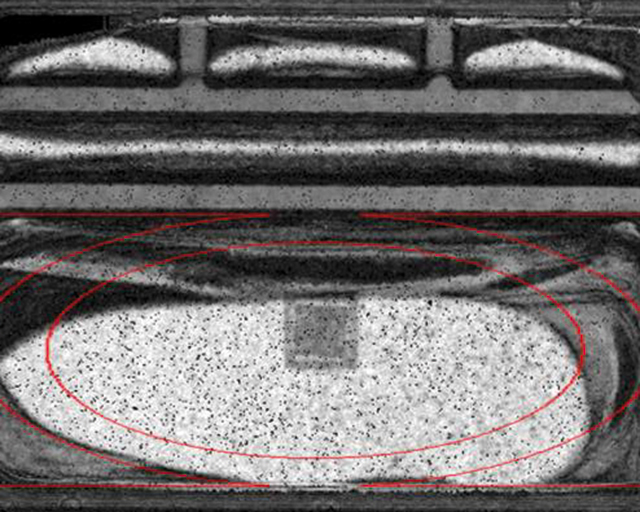

- Radiography / computer tomography

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB