Shape Optimization of Heat Sink Structures

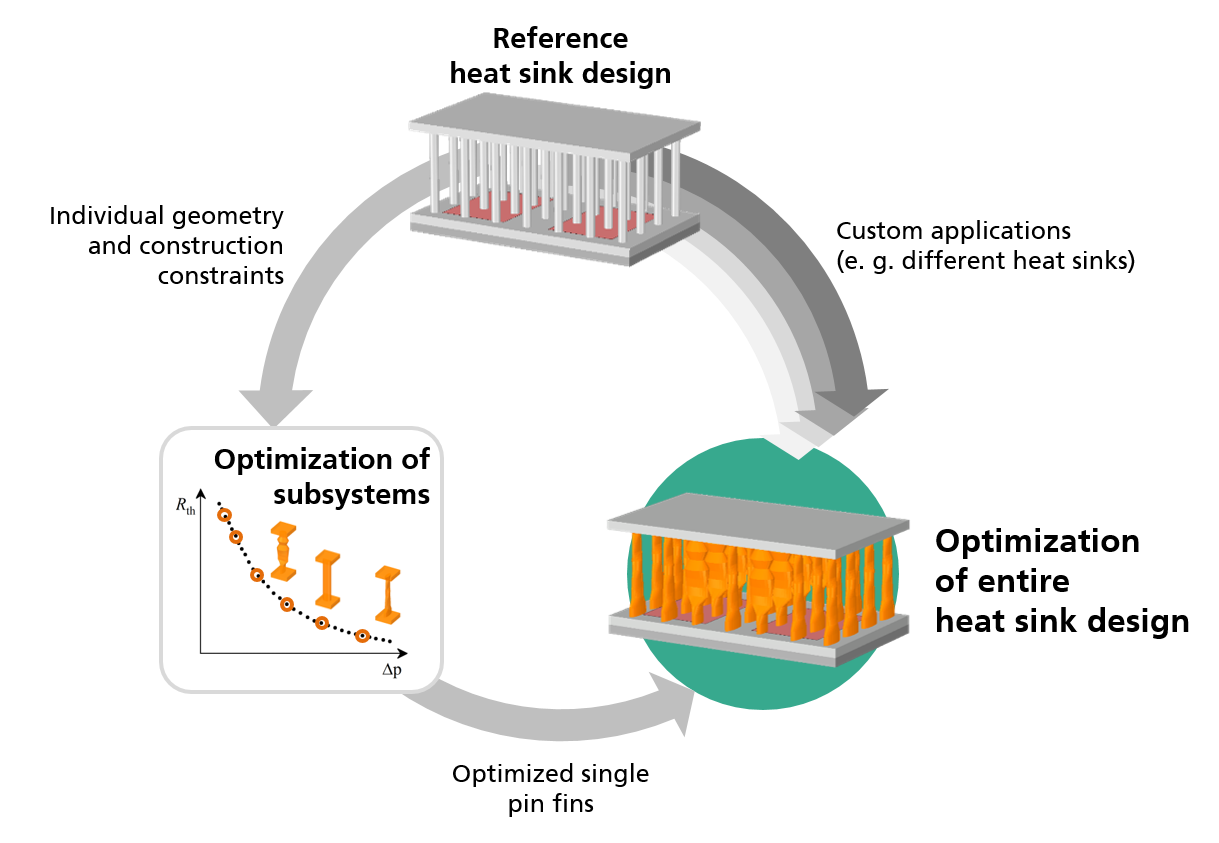

A promising method to improve heat sink designs is shape optimization. Though implementations already exist for some simulation tools, the usage for industrial applications is not yet feasible since it requires adjustments of the methodology and comprehensive understanding of the theory and numerical limitations. Therefore, the shape optimization approach is further developed, adapted and applied for the design of efficient heat sinks in the field of power electronics cooling.

This approach enables optimization beyond standard and general assumptions by taking application specific boundary conditions into account. Based on conjugate convective heat transfer simulations, the shape of the heat sink structure is thereby iteratively morphed to match the objective goals and custom constraints.

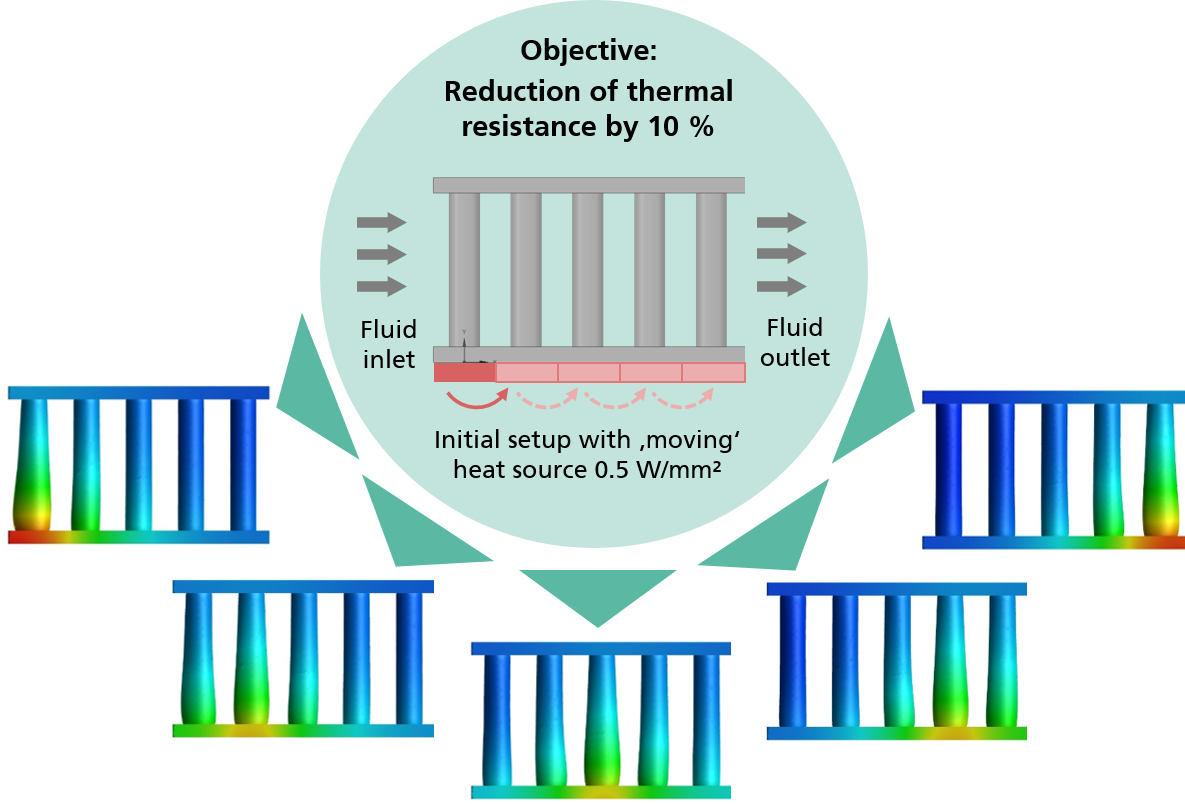

When considering individual local distributions of the heat sources, various optimal shape modifications of the heat sink may emerge having different optimization potential. This is shown in Figure 1, where the thermal resistance of a pin fin array with different heat source locations is reduced by 10 % each. This becomes even more relevant for applications such as avionics, with high demands on the heat sink efficiency, as well as a lightweight and compact design.

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB