We develop and investigate sustainable battery technologies, in particular rechargeable aluminum-ion batteries (AIB) as cost-effective and non-combustible electrical energy storage solutions. In order to be able to characterize novel battery technologies under conditions as close as possible to the application, we prepare pouch cell prototypes that are tailored to the individual requirements of the cell chemistry. Our materials research is accompanied by comprehensive (structural) analysis, where the materials are examined in their initial state, under operando conditions and post-mortem. This makes it possible to understand the energy storage processes as well as ageing and failure mechanisms.

Battery Materials

The rechargeable aluminum-ion battery (AIB) is a cost-effective and non-flammable energy storage technology based on the easily obtainable active materials aluminum and graphite. With natural graphite as the cathode material, energy densities of 160 Wh/kg and power densities > 9 kW/kg can be achieved. As a high-power storage device, the AIB can therefore be charged and discharged in a very short time at high C rates. The reversible process allows more than 10,000 cycles at 100 % DOD in laboratory test cells, with consistently high Coulomb efficiency of almost 100% and energy efficiency of > 85 %. The corrosion-resistant multi-layer pouch cells specifically developed for AIB have a capacity of up to 200 mAh and achieve a service life of more than 1,000 cycles depending on the charge rate (> 1,000 cycles for 4-layer 200 mAh cells at 6 C, > 7,000 cycles for single-layer 30 mAh cells at 30 C). Al-ion batteries have great potential for stationary and hybrid mobile applications, especially as high-performance storage devices, e.g. for dynamic grid stabilization and for UPS systems.

Services

- Synthesis and development of sustainable active and passive materials for Li-free battery technologies

- Packaging technology for Al-ion pouch cells

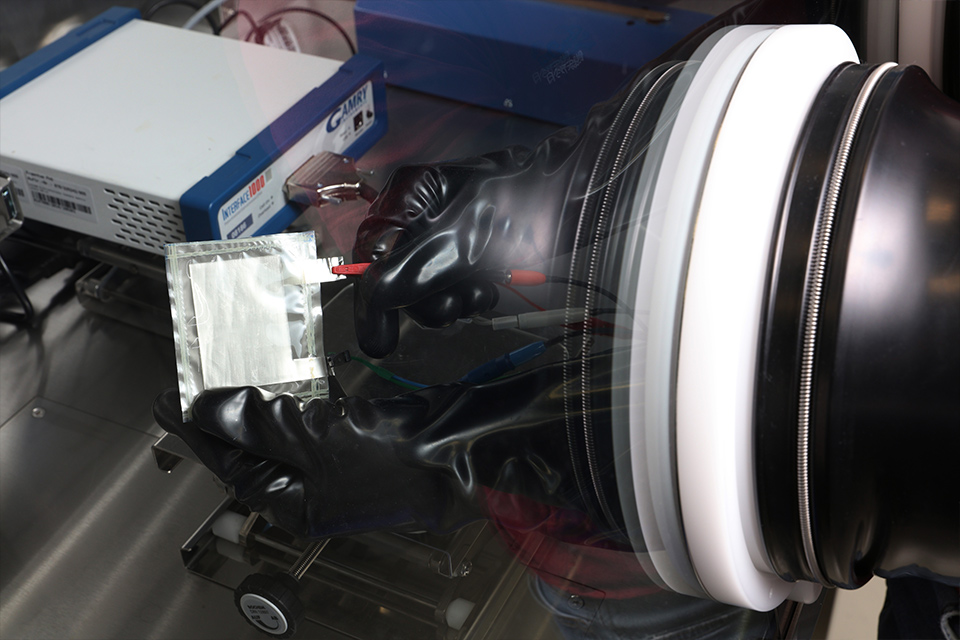

New battery materials are often evaluated in laboratory test cells or button cells during the development stage. However, tests under application-relevant conditions in larger battery cells are required for a realistic assessment of potential application on a commercial scale. Fraunhofer IISB is therefore developing pouch cell prototypes for new battery technologies. Depending on the requirements of the particular cell chemistry, adapted materials or specialized designs are used for the single-layer or multi-layer cells. One example is the aluminum-ion battery, for which special pouch cell casing materials and current collectors are used due to a highly corrosive electrolyte. Various potentiostats and specialized laboratory test cells are available for the electrochemical characterization of individual battery components up to multi-layer pouch cells. The automated evaluation of the U/I characteristics for charge/discharge cycles is carried out using Python.

Services

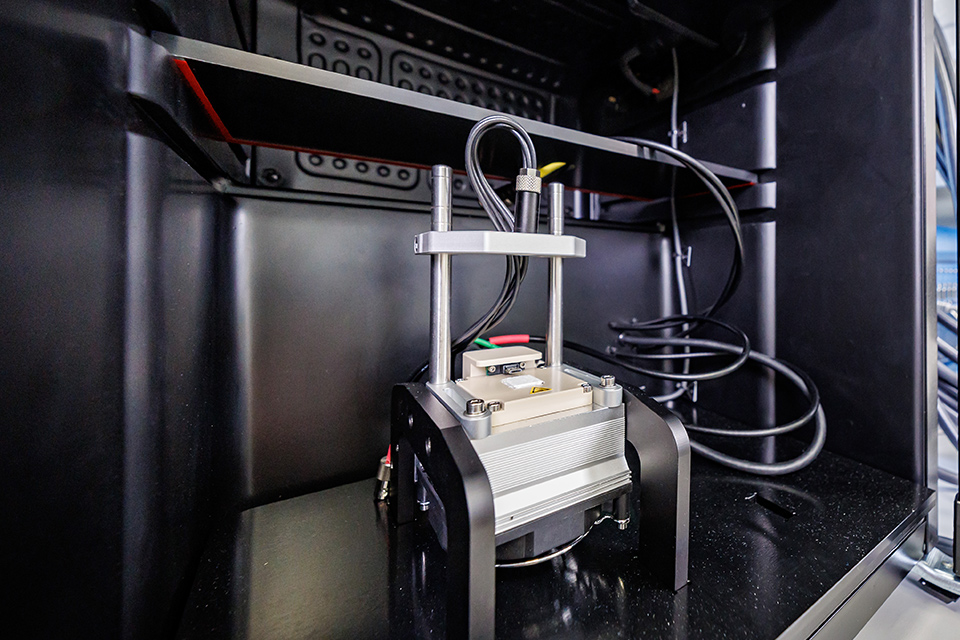

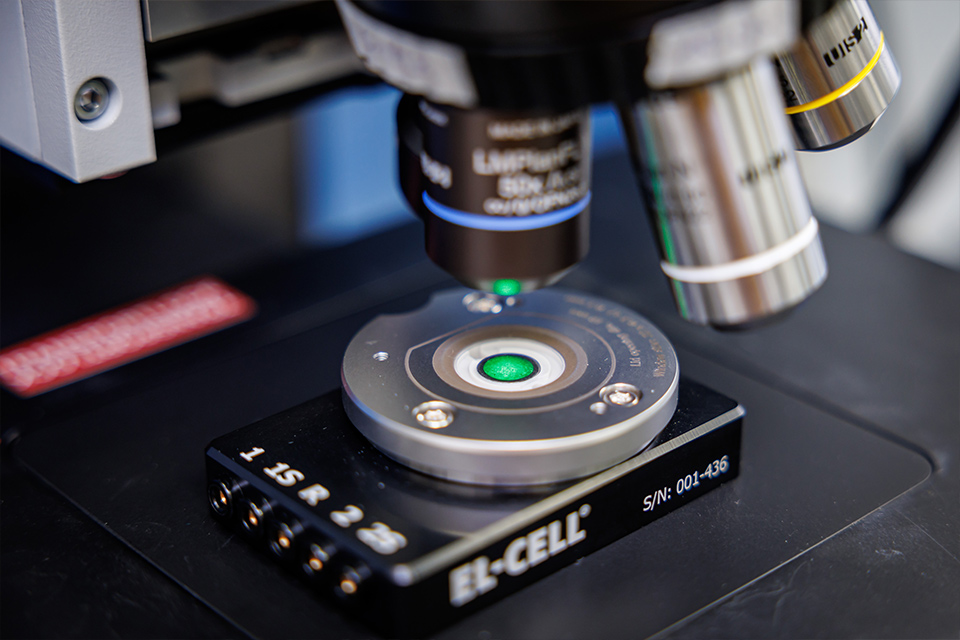

- Characterization of battery materials and components in half and full cells (e.g. Swagelok / EL-CELL laboratory test cells), possible under defined temperature conditions (climatic chamber) or in an inert atmosphere (glovebox)

- Potentiostats (incl. EIS) and battery cyclers for specific requirements

- Determination of temperature-dependent ionic conductivity of electrolytes using EIS

- Electrochemical surface analysis of electrodes

- Development and manufacturing of pouch cell prototypes for specific requirements of new cell chemistry types

- Half-cell studies in pouch cells using an integrated reference electrode

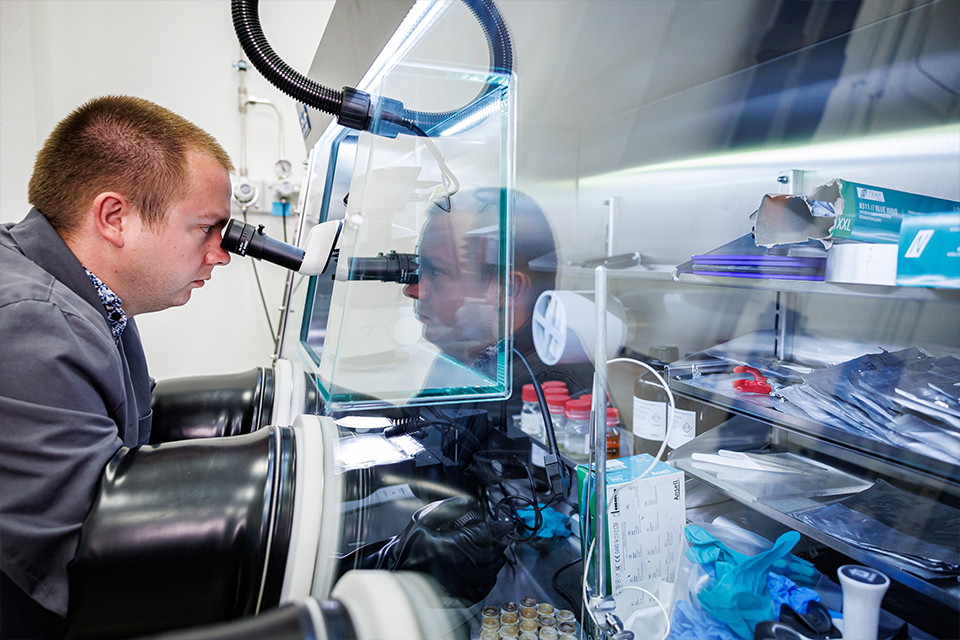

- Post-mortem analysis under inert conditions (e.g. using a glovebox microscope)

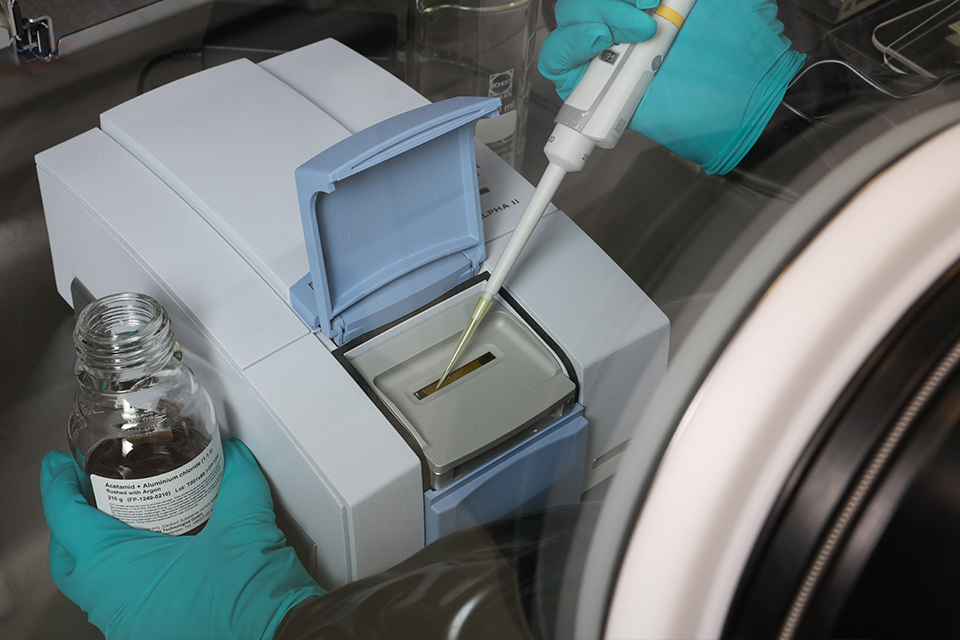

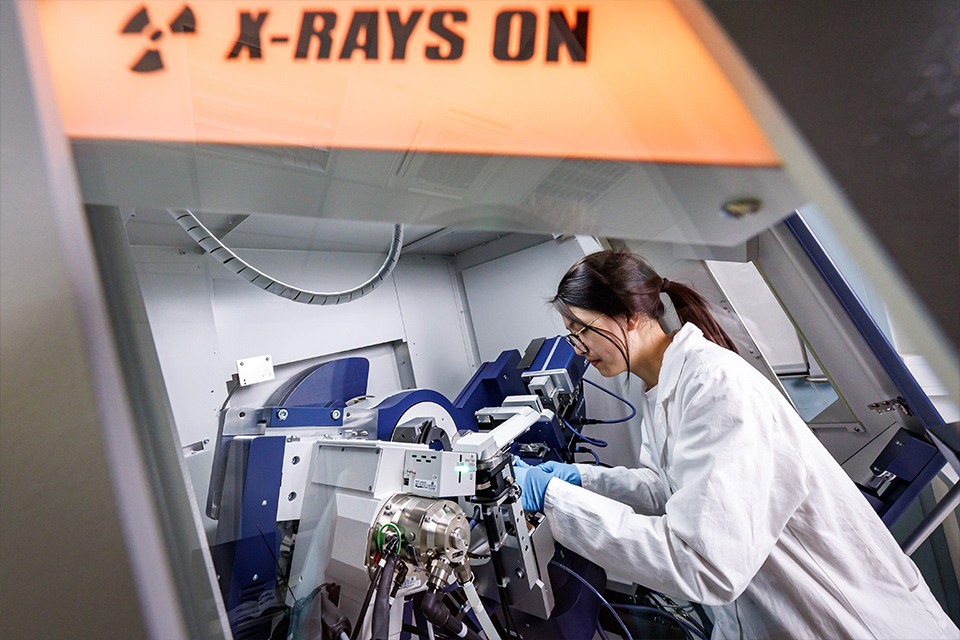

The targeted development of new battery materials requires the analysis of material structure and battery property correlations. For this purpose, the materials used are comprehensively characterized microstructurally both in their initial state and under operando and post-mortem conditions. This requires specific operando test cells and window materials for the respective cell chemistry and analysis method. For the investigation of failure and ageing processes, post-mortem analyses are carried out under inert conditions in order to examine the materials as unaltered as possible.

Services

- Powder XRD incl. operando option in Bragg-Brentano geometry (Rigaku SmartLab) or in transmission (Stoe Stadi P), inert conditions possible

- Raman spectroscopy (Horiba LabRam Odyssey) incl. operando option, measurement of solid and liquid samples, inert conditions possible

- Development, adaptation and evaluation of operando measuring cells and window materials for specific requirements

- ATR-IR spectroscopy under inert conditions in the glovebox

- SEM/EDX examinations, inert conditions possible

- Light microscopy, inert conditions possible

- Determination of the water content of solid battery components using Karl Fischer titration

- Particle size distribution via dynamic light scattering

- Determination of BET surface area and pore size using nitrogen adsorption

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB