Bidirectional 6kW Charger Using GaN Devices

Insulated and Bidirectional On-board Charger With Normally-Off GaN Gate Injection Transistors

New power semiconductors such as 600 V normally-off GaN gate injection transistors (GaN GITs) offer new opportunities for power topologies especially in bidirectional power-flow applications. There are very interesting implementations in bidirectional on-board chargers (OBC) for electric vehicles. Here, a bidirectional energy flow can either be used for vehicle-to-grid scenarios or for providing a high-power on-board AC socket. Because of a very low output capacitance and the ability of reverse current operation, GaN GITs offer advantages in hard switching topologies (low switching losses) as well as in soft switching topologies, where no additional leakage inductance is necessary.

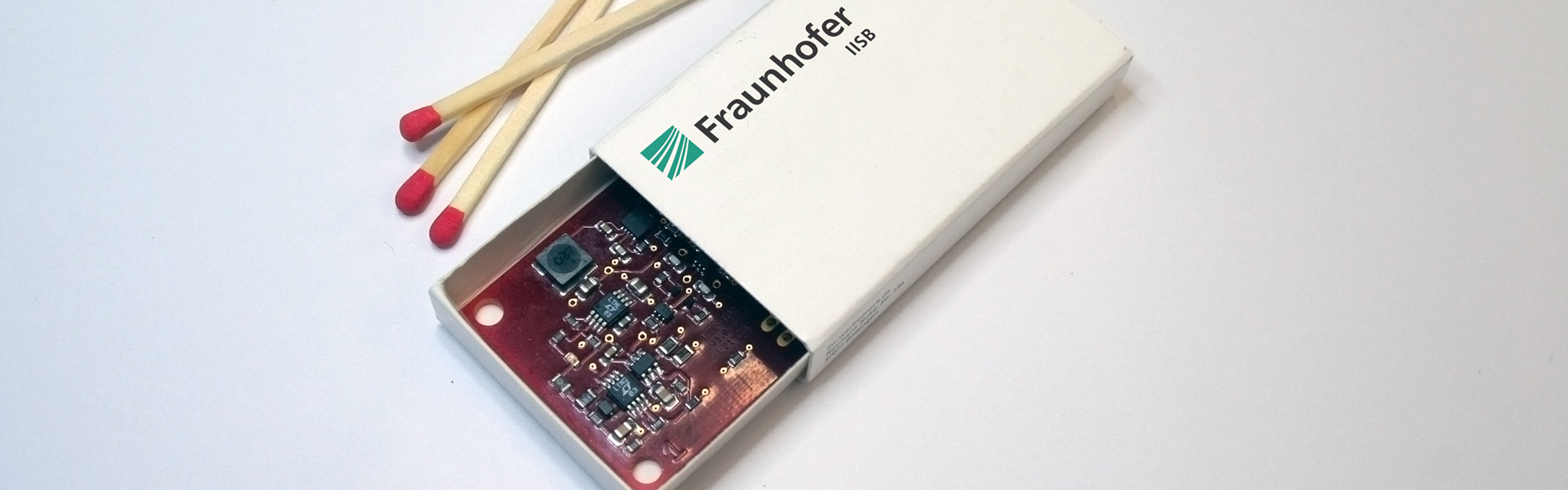

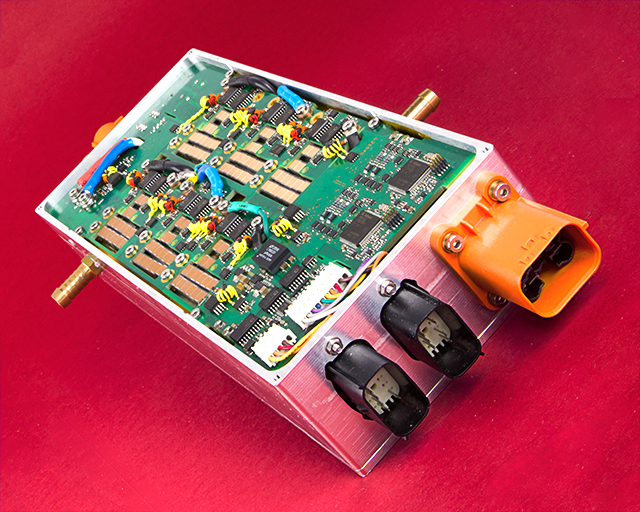

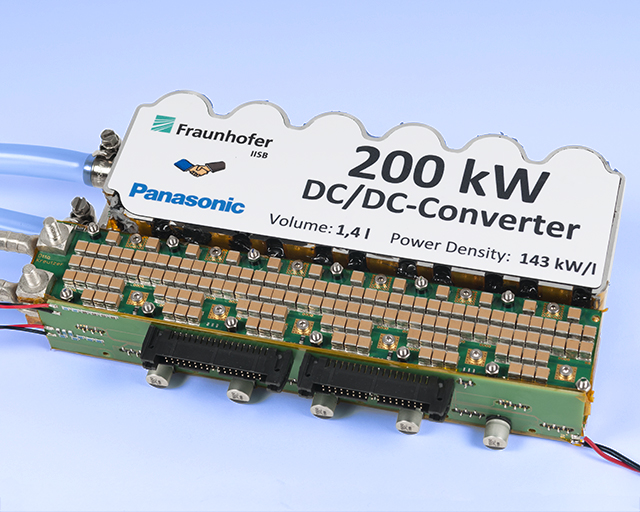

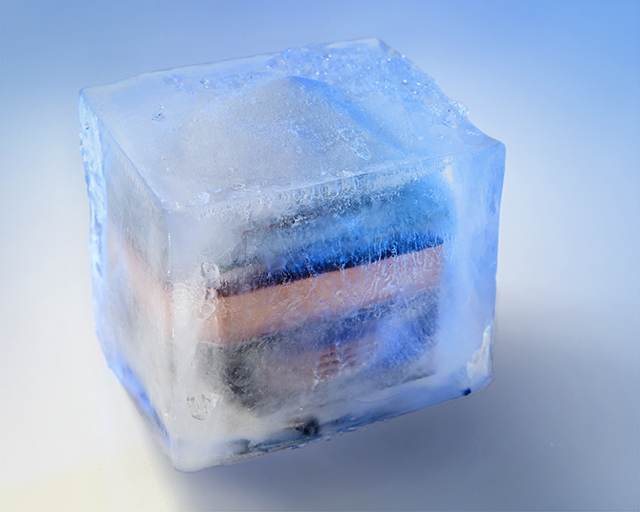

Within a bilateral project with Panasonic, the Fraunhofer IISB has developed a bidirectional insulated OBC specially designed for the customer. The result was a novel 6 kW OBC with normally-off GaN gate injection transistors from Panasonic presented within only 2 dm³. The OBC is fully digitally controlled by using a special current regulator technique to reduce the higher grid harmonics. The utilized insulated power stage works like a DC transformer, determining primary-side DC operation voltage without applying any voltage regulator. The two-phase OBC consists of six equal full-bridge power modules next to the gate driver circuitry and DC link capacitors following a modularized approach.

A very high power density of approx. 3 kW/dm³ was reached with the developed prototype - which means an outstanding value for a complex bidirectional galvanically insulated OBC.

Challenges and solutions

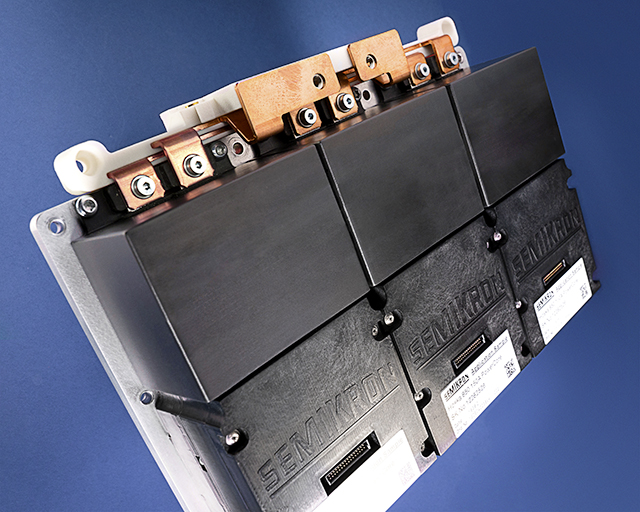

To obtain the full performance of modern wide-band-gap power semiconductors such as GaN GITs, a low inductive realization of the switching power paths is necessary. Hence full-bridge power modules were developed with four 600 V (34 mΩ) Panasonic normally-off GaN GITs soldered and bonded on a FR4 together with gate drive units and DC-link capacitors.

To obtain a high efficiency OBC, a modern totem-pole circuit topology for converting the AC mains voltage to an internal DC-link voltage was chosen. For the galvanically insulated power stage, a low-loss soft-switching so-called CLLC converter was used. For extending the very efficient operation area, a switchable variable transformer ratio was implemented.

Hence, the AC/DC as well as the insulated DC/DC power stage achieve approx. 98% efficiency.

The performance of modern power electronic systems is not only dominated by power semiconductors but by control circuits as well. In this project, the 6 kW output power was divided into two identical 3 kW units each controlled by a 32 bit micro controller. Each microcontroller controls 12 power switches at a high switching frequency at approx. 130 kHz. Due to restrictions of the higher harmonic 50/60Hz grid frequency, the control of sinusoidal AC mains current is important. For this, a special version of the so-called low bandwidth current mode control technique, which is based on a non-linear feed forward control method, could be successfully implemented.

Due to the chosen double 3 kW power units, the OBC can be also used on two phases of the common three-phase 400 V AC mains system. In this case, the battery current has a pure DC portion with a superimposed AC sinusoidal content.

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB