Packaging for Electronics

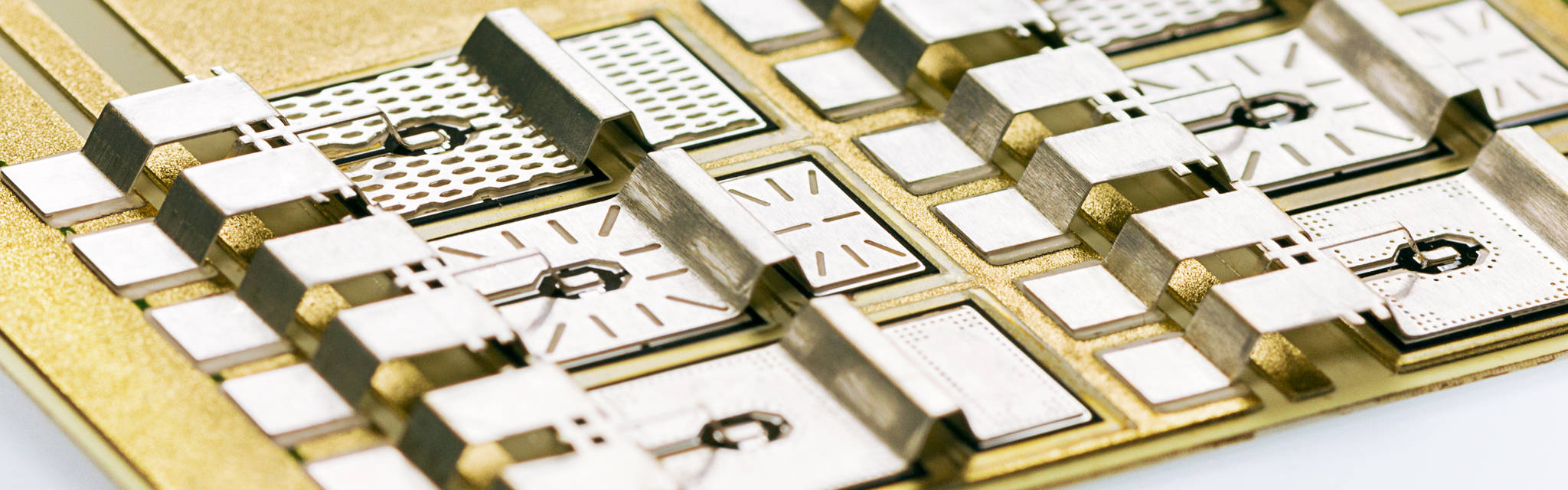

Motivation for Ceramic Embedding:

- Miniaturization & no housing, 3D-integration, reduction of connection points

- High switching & short current paths, vias instead of bond wires, low parasitic inductance

- More efficient cooling & double-sided cooling, thermal vias

- High temperature capability (> 200 °C)

- High thermal conductivity (Al2O3, AlN, Si3N4)

- High current carrying capability (Cu layer > 300 µm), no wires

- High corrosion resistance (ceramic)

- Low CTE-Mismatch

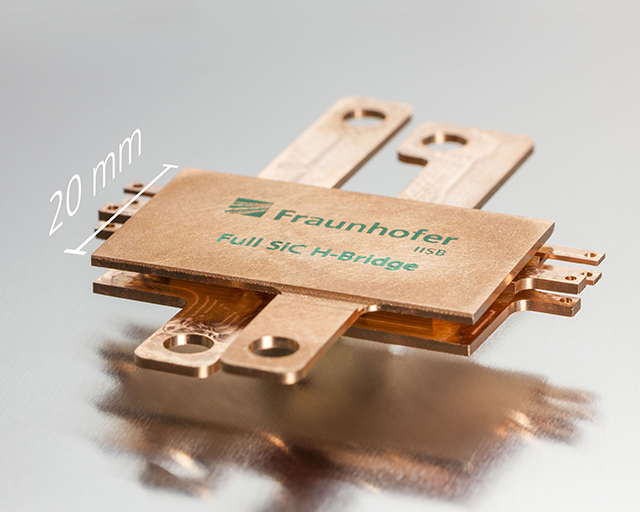

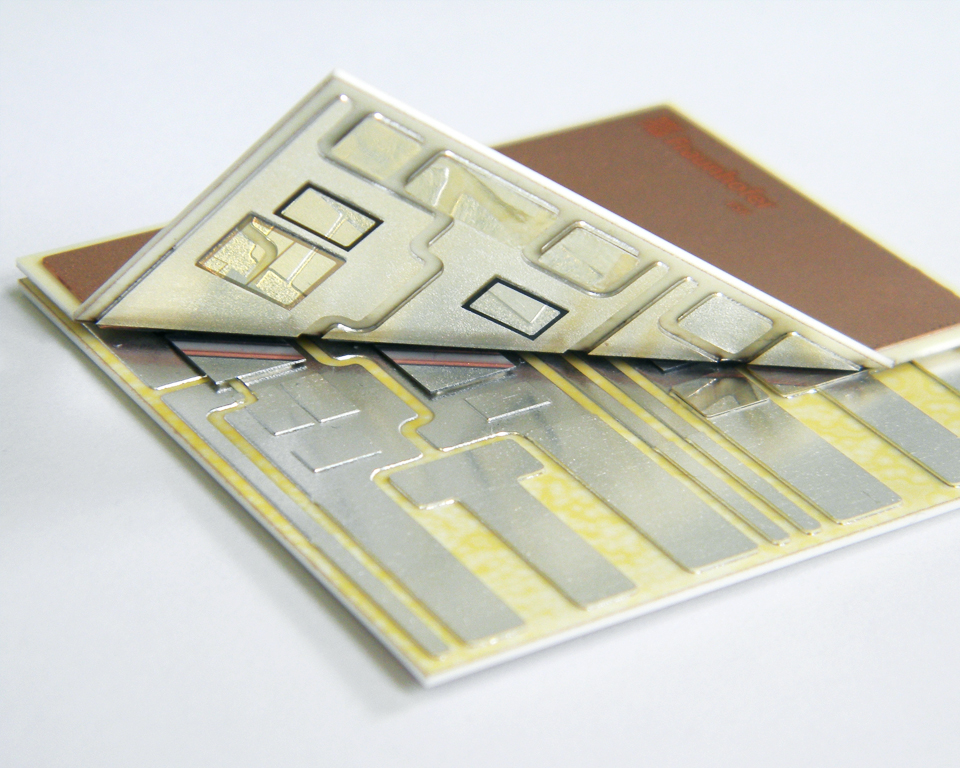

Full SiC Double Sided Busbar Module

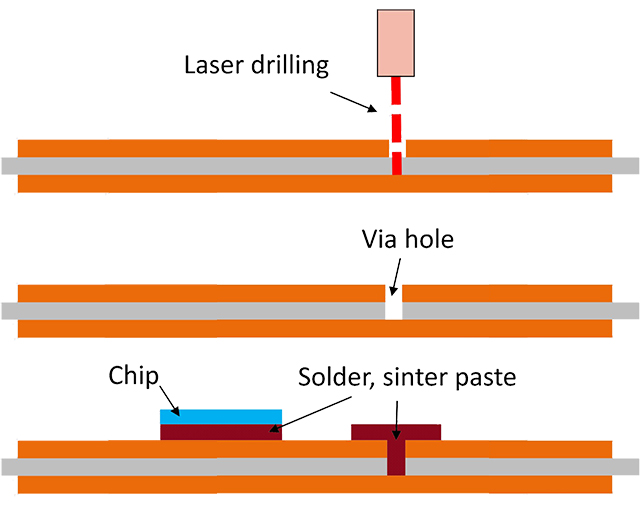

Idea of concept

- Low inductance and high temperature power module for e-drives

- Fast switching with SiC

- DC+ & DC- on outer metalliztion for lowest parasitic C to ground

- High reliability and temperature capability by silver sintering

- Low cost due to copper busbars with hybrid polymer isulation layers instead of DBC substrates

- Double sided cooling, high thermal capability

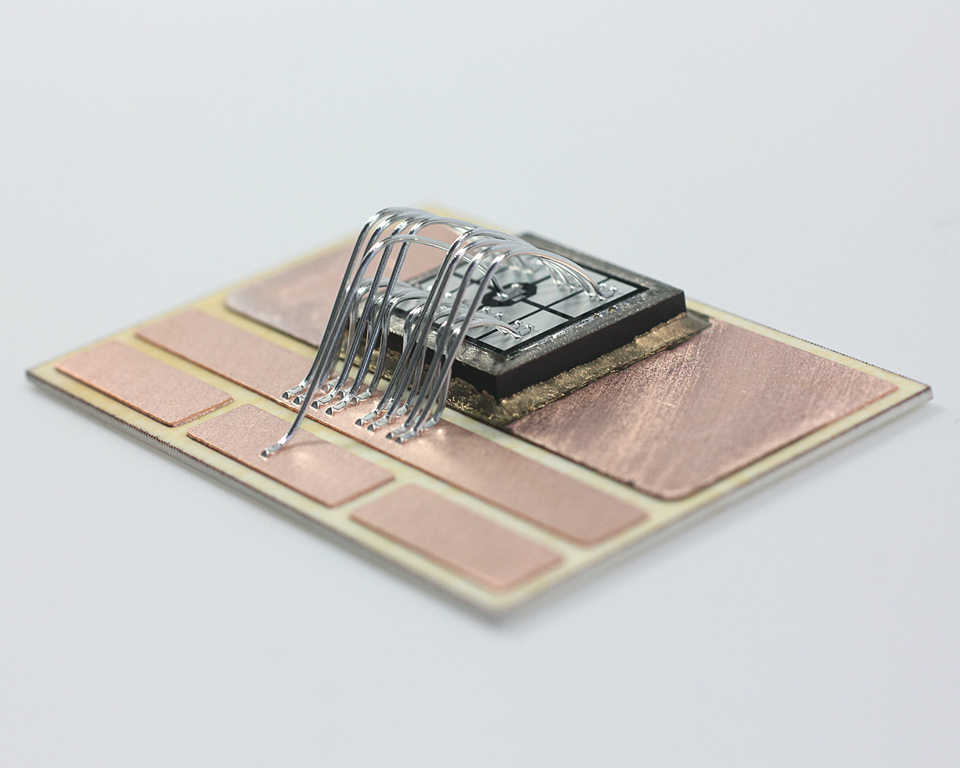

Further examples of our prototypes

Equipment

- Multi-physics simulation tools (electro-thermo-mechanical), CAD

- Plasma cleaning

- Printer for paste material

- Vapor-phase vacuum soldering

- Formic-acid-activated IR vacuum reflow

- Hydrogen activated IR vacuum reflow

- Full automatic die placer with high temperature and extended tool force capability

- Automatic wire and ribbon bonders (Al, Cu, Au)

- Servo press for sintering

- Ultrasonic and resistance welding machines for electric terminals

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB