We use spray coating of e.g. SiO2, Si3N4 and SiC to functionalize crucibles and other furnace parts in order to reduce harmful defects and impurities and to increase the lifetime of the furnace parts. For Cz silica crucibles we have a qualified vacuum bake out test procedure in order to investigate bubble behavior and cristobalite formation. Another focus is on ultra-high-temperature and chemical resistant protective TaC coatings on graphite and other materials. We develop this novel patented technology for applications in semiconductor industry, especially for SiC PVT crystal growth and epitaxy, but we address also space and aviation applications.

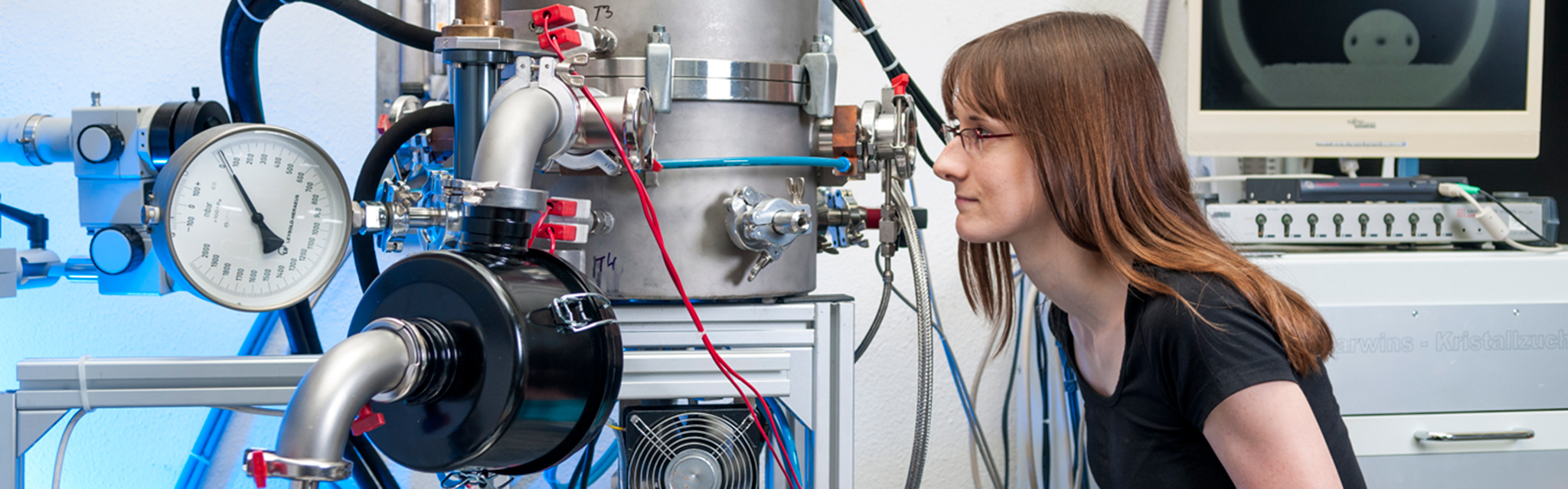

Functional Coatings (SiO2, Si3N4, SiC, TaC)

Services

- Spray coating of SiO2, Si3N4, SiC, and TaC

on graphite, silica, ceramics, refractory metals - Analysis of wetting behavior of silicon and other melts according to the sessile drop method

- Vacuum bake out test and analysis of Cz crucibles

- Microstructural characterization of coatings and crucibles

- Test of coatings under application conditions

Functional Coatings

Based on our expertise in the field of coatings, we are developing a novel technology for ultra-high-temperature-resistant protective coatings for space applications. The HOSSA project focusses on the application of ceramic protective coatings to fiber composites using powder coating technology. The goal is to bring the advantages of fiber composite components, such as high breaking elongation, high crack resistance, and high dynamic load capacity, to new applications by increasing heat and oxidation resistance as well as improved mechanical abrasion resistance. The patented technology offers a significant cost advantage over conventional coating processes and is also suitable for repairing components. HOSSA can be used to increase the efficiency of drives and the exposure time of re-entry vehicles. The protective coatings can also be used in aircraft and helicopter engines and gas turbines.

IISB insights: Functional Coatings in 90 Seconds

Benefits:

- Customizable coating technology to achieve a variety of coating properties

- Cost-effective technology with great flexibility in terms of size and geometry of the components to be protected

- Allows use of fiber matrix composites in new applications

- Higher combustion temperatures and therefore increased efficiency of rocket engines and boosters

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB