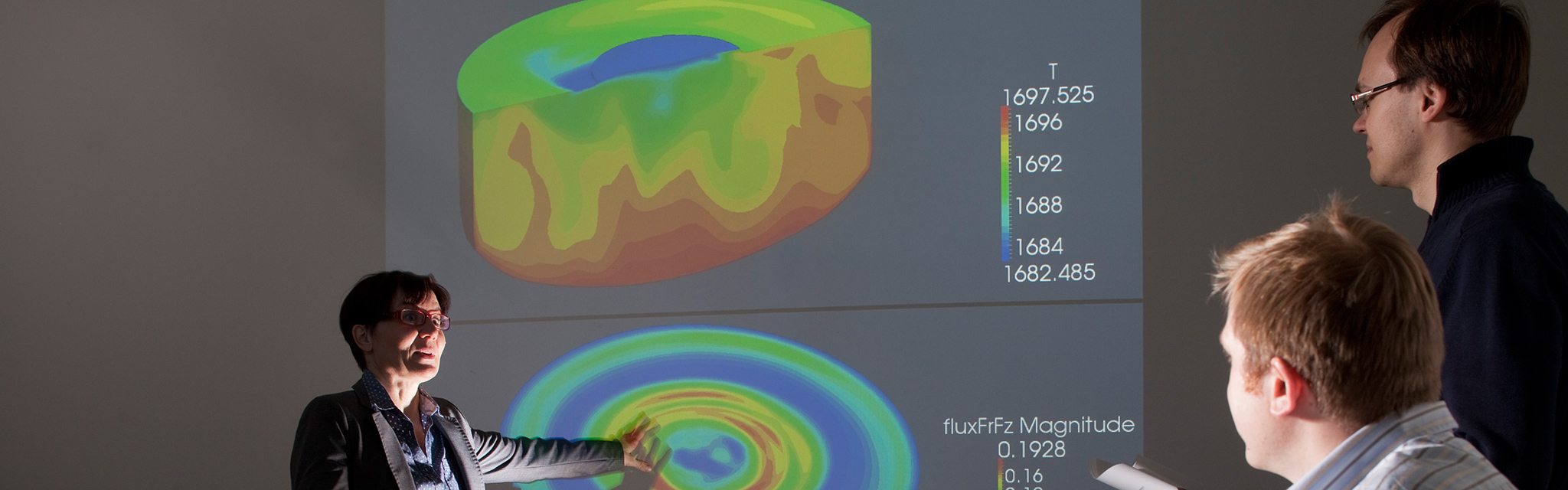

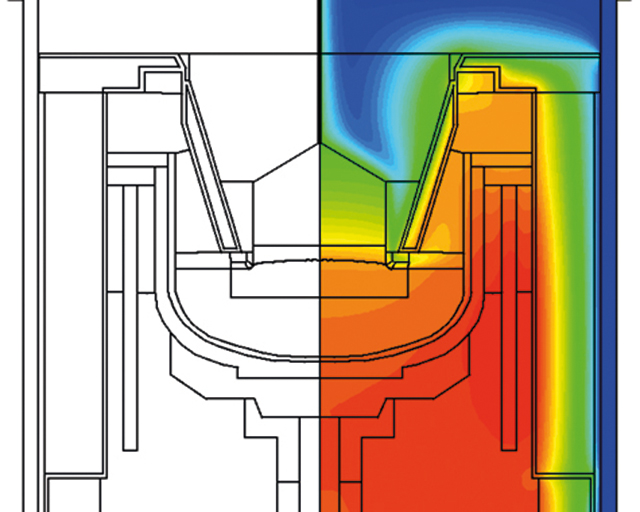

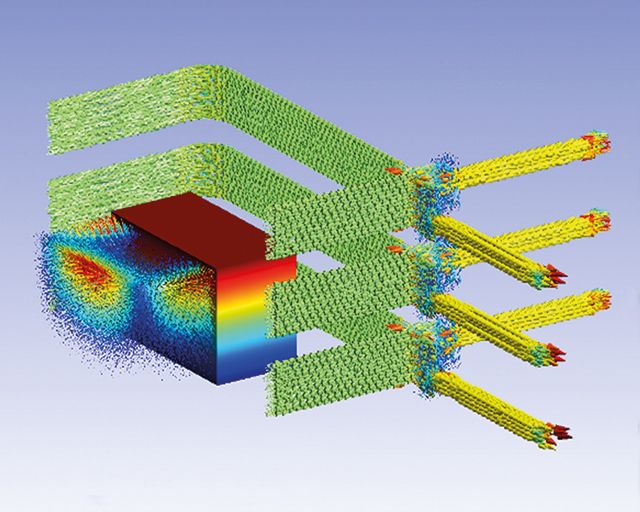

We support the development of high-temperature equipment and processes by our expertise in numerical modeling of heat and mass transport phenomena. Specific expertise is available for crystal growth and epitaxial processes. We are also experienced with other thermal processes like e.g. wafer annealing. We elaborate solutions for furnace modifications in order to optimize the systems for the respective application and we give new insights into the processes, especially for parameters that are hardly accessible via measuring techniques like species distributions or convection pattern.

Equipment Simulation

Services

- Thermal simulations (conduction, convection, radiation)

- Flow simulations (gas, melt, turbulence including magnetohydrodynamics)

- Stress simulations

- Electromagnetic field simulations

- Simulation of species transport including chemical reactions

- Software tools: CrysMAS, OpenFOAM, Ansys

- Processes: Cz, VGF, DS, FZ, EFG, LPE, THM, CVD, PVT, HVPE, annealing

- Materials: Si, Ge, GaAs, InP, GaN, AlN, SiC, CdZnTe, halides, oxides

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB